In the automotive door assembly door inner panel is divided into different thickness without reinforcement components and different thickness sheets laser plates are assembled by welding.

Car door manufacturing process pdf.

109 3 kg 920 9 kg of input 70 1 kg losses in processing steel 850 8 kg into making parts 67 6 kg losses during manufacturing 783 2 kg into new car 76 7 kg losses during use abandoned cars 706 5 kg of hulk going to dismantler 25 9 kg losses in dismantling recycling.

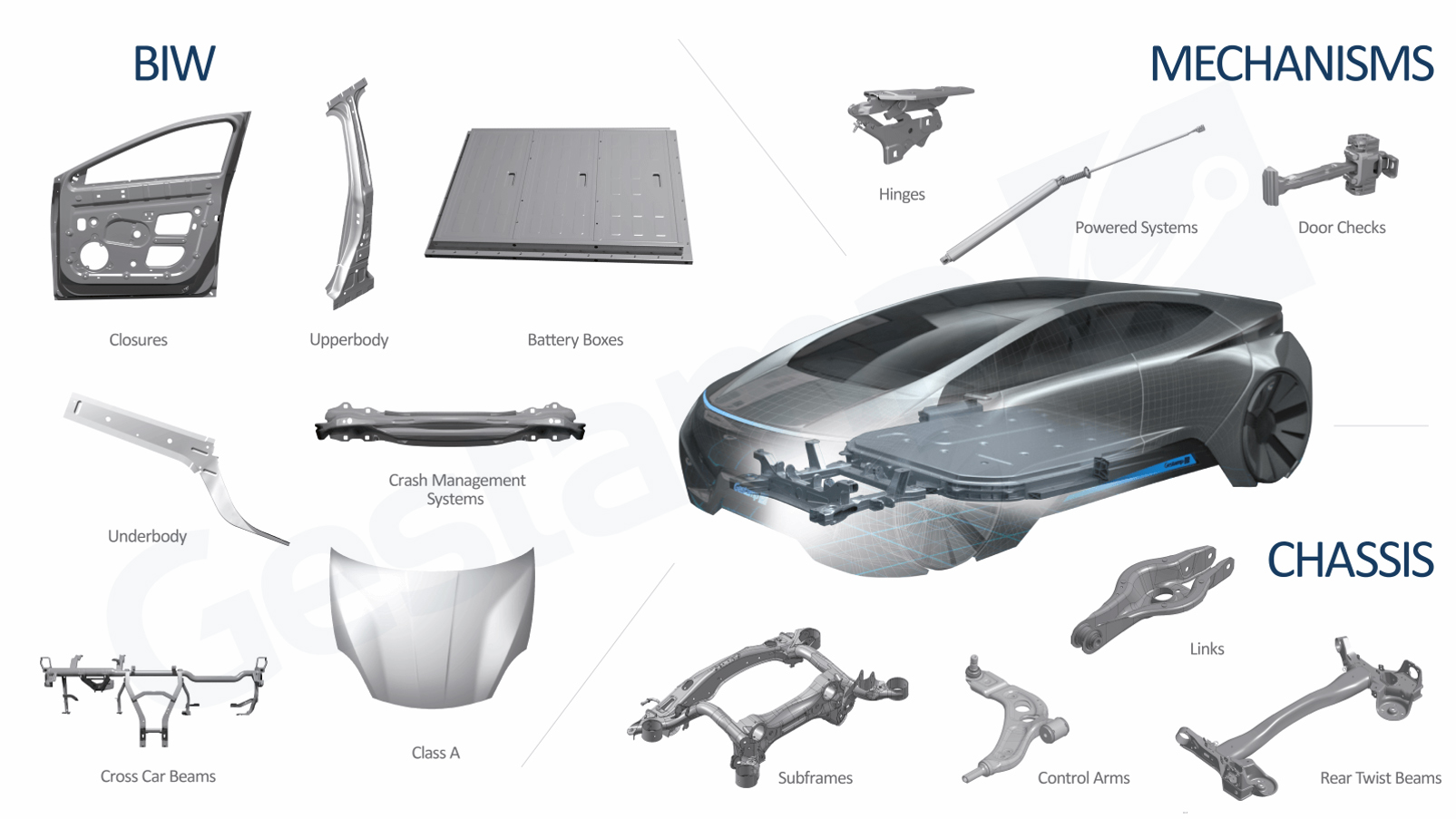

The assembly process is in turn divided into a number of sub processes which includr fitting car doors to body openings.

Explore alternate design process methodology and application of plastic material for door module in car body application.

These panels should be designed to withstand and channel loads into the body of the car while being thin 2 mm.

This byline captures ais culture.

These doors can be opened manually or powered electronically.

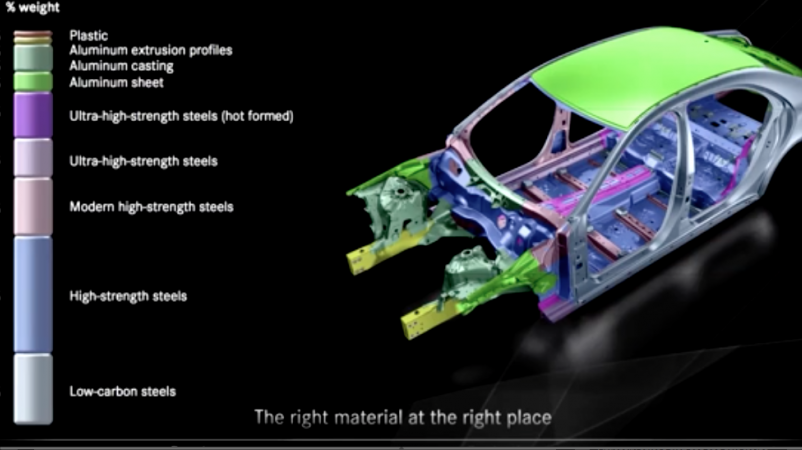

Simultaneously the steel content of the car is falling with the use of aluminium and new materials such as plastics.

With major investments in place the.

Mission jikko execution for excellence.

To transcend the ordinary.

A prominent area of application for such criteria in the automotive indusuy is the body assembly process.

Today s cars are primarily sourced out to produce various sub assemblies in over 4 000 disparate locations as far away as china.

A car door is a type of door typically hinged but sometimes attached by other mechanisms such as tracks in front of an opening which is used for entering and exiting a vehicle a vehicle door can be opened to provide access to the opening or closed to secure it.

An intensive research and development are going on for alternate materials manufacturing processes and stamping tools for sheet metal components with the main objectives of cutting down the weight and unit cost of the vehicle.

Technique is utilized for lightweight door design and a design process is proposed for optimizing the automobile twb door.

Door panels are expected to meet one of the toughest sets of requirements among interior car components.

To understand the car manufacturing process you have to understand the underlying supply chain that drives domestic vehicle assembly.

2 1 definition of the problem to design and analyze a plastic door module for car body application to achieve a weight reduction of 20 compared to existing weight of steel door module.

These loads could be horizontal and vertical in nature like the force applied on opening or closing doors while leaning resting on them or when stepping on the armrest to.

811 6 kg recycled steel.

Pressed stamped sheared trimmed hemmings etc very fast high quality large batches customization small batches high price forces needed in pressing 100 to 1000 ton presses are commonly seen in videos in shearing 210kn forces with 300mpa uts 1mm thickness and 500x500mm.

Steel on a per car basis 1995 numbers new steel.